Hybrid technologies: examples of applications Organic solvent filtration After decades of successful application in water, membrane separation processes have recently received substantial attention in attempts to integrate them in processes occurring in organic solvents. Nanofiltration and pervaporation which are widely accepted as separation technologies for the treatment of aqueous streams, are now on the threshold of being industrially applied in organic solvents as well. Particularly solvent resistant nanofiltration (SRNF) and organophilic pervaporation (OPV), hold an enormous application potential since they allow to separate organic mixtures down to a molecular level by simply applying a pressure gradient over a membrane or a low vacuum at the permeate side, respectively. Both techniques have most potential as a complement in a hybrid process to complement or upgrade existing production facilities based on more traditional separation processes (distillations, evaporations, chromatographic separations, crystallizations, adsorptions or extractions). For applications allowing only low thermal stress or using non-volatile solvents, on the other hand, membrane technology can be the only technical solution. Most applications are found in food processing, pharmaceutical and fine chemical synthesis, catalysis and petrochemical refineries. |

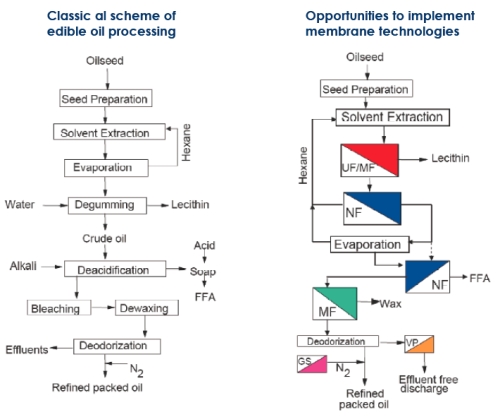

• Food processing Most processes in the food industry are evidently aqueous, but in some cases, organic solvents are extensively used. Solvents are in first instance applied in the vegetable oil industry, (for fractionation and extraction) and in the synthesis of some food additives. Compared to the classical processes applied in oil processing, membrane technology avoids the use of additional chemicals or high-temperature treatments, thus minimizing waste streams, energy consumption and thermal damage to the products. Membrane-based solvent filtration allows solvent recycling and separation of molecules in a customized manner. There are several steps in edible oil processing where integration of membrane-based solvent filtrations offers opportunities by replacing or supplementing conventional approaches, UF membranes have been used for degumming, while SRNF can be applied for the removal of oxidationsensitive free fatty acids and for the recovery of extraction solvents. |

|

As a mild, non-thermal and thus non-destructive separation technique able to separate water/organic solvent mixtures, OPV is more and more used for the isolation and purification of natural aromas which are often used as high value food ingredients. The challenge of maintaining ingredient functionality (flavor, color, texture, etc.) during processing is driven by consumer preferences relating to health and food safety, and for ‘original’ or natural characteristics. OPV provides and alternative to thermally driven methods for isolating highly concentrated natural aroma extracts from highly diluted aqueous solutions. |

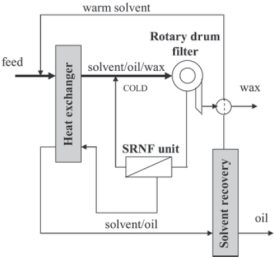

• Petrochemical refineries The largest scale on which membrane technology has been introduced so far in liquid-phase organic processes is in petrochemistry, more specifically in the refining of lubricants. The refining industry is both energy- and separations-intensive, and is often accompanied by a large exhaust of organic solvents, suggesting that large-scale membrane systems can provide significant benefits. The best-known and most successful application of SRNF to date has been in ExxonMobil’s MAX-DEWAX process, installed in 1998, which is employed for crude oil dewaxing at a 72000 barrels per day scale. The lube oil filtrate is treated in a SRNF installation using spiral-wound polyimide membranes achieving lube oil rejections of more than 95%. |

|

|

By replacing the evaporation step with a SRNF-membrane, a 99% pure solvent mixture could be obtained at refrigeration temperature, which could be directly recycled to the chilled feed stream, without the need for additional cooling. The capital investment for the SRNF was only 1/3 compared to the costs for the same capacity increase using conventional technologies. The SRNF-assisted process only needs 25% of the heat consumption, 20% of the size and 10% of the refrigeration capacity, resulting in a pay-back time of less than 1 year. The anticipated membrane lifetime of 1.5 years has meanwhile been largely passed, demonstrating the robustness of the polymeric membrane. This highly successful application at large scale clearly shows the potential for SRNF to impact the energy and chemical sectors. Other SRNF/OPV-based refi ning applications that are currently investigated include desulphurization of gasoline, deacidifi cation of crude oil, aromatics enrichments of various refi nery streams, benzene reduction in naphta, and polar/non-polar separations. |

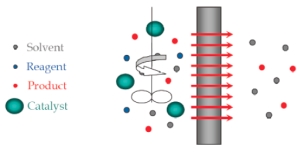

| • Homogeneous catalysis The separation of reaction products from catalysts is a major problem in many types of homogeneous catalysis. Usually, homogeneous catalysts are relatively large, and the reaction products substantially smaller, so that separation is feasible with SRNF. In parallel with the advent of several commercial SRNF membranes, important efforts have been devoted over the past years to the separation of homogeneous catalysts from their reaction mixtures in order to recycle the catalyst and/or facilitate product purification. Coupling with SRNF now allows to efficiently use and re-use highly active and selective homogeneous catalyst with all the advantages of heterogeneous catalysis, such as easy catalyst separation, straightforward product isolation and continuous operation. |

|

Removal of homogeneous catalysts is currently most commonly achieved via distillation, chromatography or extraction. Whenever SRNF is chosen to recover homogeneous catalysts, very high catalyst rejections and a long-term catalyst stability are absolutely necessary in order to be economically viable. If a membrane is not sufficiently resistant to the pressure and temperature conditions needed for reaction, continuous membrane reactors are excluded and only batchwise filtration-reaction cycles can be applied then. Evonik (the former Degussa) successfully integrated a SRNF membrane installation in its hydroformylation unit to separate and recycle the homogeneous rhodium (Rh) catalyst. Given the price of Rh (approximately €50/g) SRNF-coupled catalyst recovery clearly means an enormous cost reduction. |

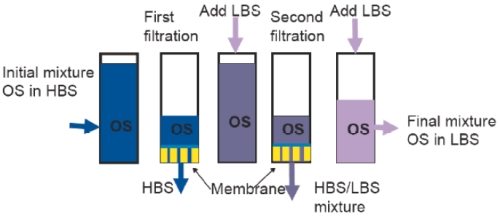

• Pharmaceutical and fine chemical synthesis Work-up and post reaction processing and separation accounts for as much as 40-70% of the total production costs of fine chemicals. SRNF has many potential applications in organic synthesis, i.e. solvent operations, product purification and natural product fractionation. Most complex organic molecules used as active pharmaceutical ingredients (APIs) are synthesized through multi-step routes involving a sequence of organic reactions. Solvent exchanges are used when a first stage (e.g. a reaction or crystallization) requires a particular solvent, and is followed by a second stage that requires a different solvent. When the first solvent has a much lower boiling point than the second solvent this is typically done by a sequence of distillations. However, since most pharmaceutical intermediates are heat sensitive, conventional distillation can only be carried out under vacuum. SRNF can be used to effect solvent exchanges at ambient temperature and regardless of azeotropic behaviour or the boiling point order of the two solvents to be exchanged. |

This means that an organic solute (OS) can be swapped from a highboiling solvent (HBS) to a low-boiling solvent (LBS). A similar approach can be adopted for the purification of APIs, i.e. for the removal (washing out) of impurities such as trace metals, unwanted reactants or polymeric impurities. |

|